New RingRecycleMe Program Creates Renewable Supply for Ring Carriers Designed to Cut Plastic Production in the midst of the global pandemic.

Itasca, Illinois – Today a new sustainability milestone has been reached in the multi-packaging industry with Hi-Cone Worldwide, the leading supplier of multi-packaging solutions for global beer, soft drink, and general product industries, and the launch of its RingRecycleMe program in partnership with Avangard Innovative, the worldwide leader in #4 LDPE plastic recycling. The two companies join forces to address the current plastic waste crisis through a circular approach that keeps ring carriers in a recycled production loop, and out of landfills and the environment.

“Since joining the Hi-Cone Worldwide team last year, one of my immediate goals was to provide consumers with the information and tools needed for them to recycle their ring carriers. I am excited to see this vision turning into reality, even during the COVID-19 pandemic, with the launch of our RingRecycleMe initiative,” said Shawn Welch, Vice President of Hi-Cone Worldwide. “Our partnership with Avangard Innovative is important to Hi-Cone because we’re working together to collect and use ring carriers to make new ones over and over again, furthering our commitment to reducing the use of virgin plastic and transitioning all ring carriers into +50% post-consumer recycled product,” Welch mentioned.

Hi-Cone’s partnership with Avangard Innovative comes at a time when food delivery and the use of disposable plastics are on the rise and U.S. consumers do not understand or trust recycling. According to Hi-Cone’s State of Plastic Recycling Annual Report 2020, only one in four Americans recycle all of their plastic waste. The report also highlights the desire to do more to ensure a more sustainable future. The launch of the RingRecycleMe program gives consumers the confidence that their ring carriers will be recycled and reused to reduce virgin plastic production and lower environmental impacts.

![]()

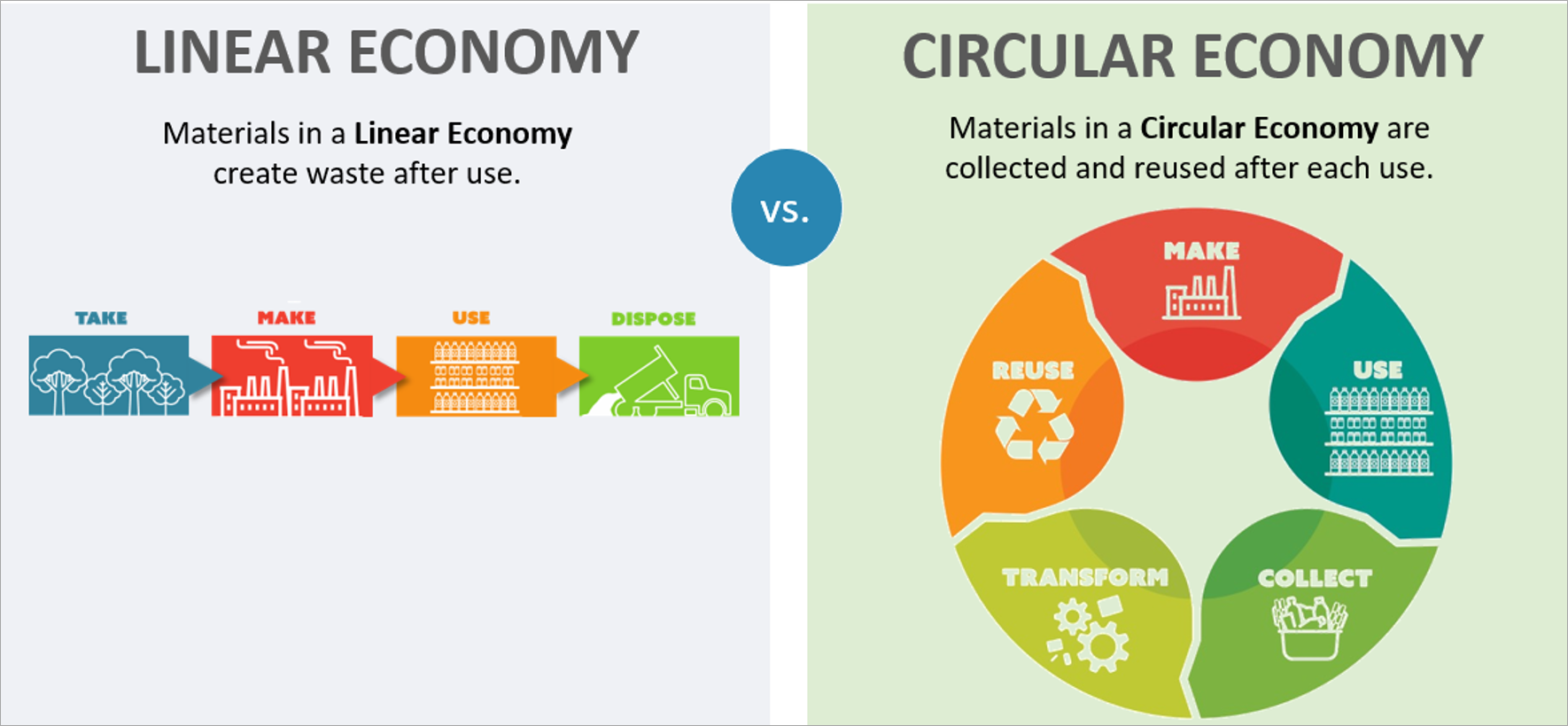

“We are excited to be a part of the RingRecycleMe initiative in partnership with Hi-Cone, as we both share a commitment to keeping plastic and other recyclables out of landfills and the environment,” said Rick Perez, CEO of Avangard Innovative. “Our participation leverages proprietary technology to measure, manage, and monetize retailers’ sustainability programs, maximizing the volume of ring carriers and other LDPE plastics reclaimed, recycled, and transformed into post-consumer resin. By using the PCR pellets to manufacture new ring carriers, Hi-Cone and Avangard Innovative will effectively create a circular economy solution,” Perez added.

The Houston-based recycling specialists for #4 LDPE or low-density polyethylene used in bags, film, and lighter plastics, Avangard Innovative will supply post-consumer recycled resin (PCR) pellets from its NaturaPCR recycling facilities to Hi-Cone for the production on its redesigned RingCycles™ packaging, which reduces the use of virgin plastic by half. Ring carriers originated as an innovative alternative to paperboard to prevent deforestation back in the 1960s. The company is currently working on a sustainable solution that is 100% recyclable, biodegradable, or compostable by 2025.

In addition to partnering with Avangard Innovative and investing in next-generation solutions, Hi-Cone partners with leading organizations around the world including the Ocean Conservancy and TerraCycle® and is part of the Ellen McArthur Foundation New Plastic Economy Global Commitment to advance the circular economy and keep plastics in use as a valuable resource.

About Hi-Cone Worldwide

Hi-Cone is a leading supplier of ring carrier multi-packaging systems for the global Beer & Non-Alcoholic Ready to Drink (NARTD) beverage markets, providing sustainable packaging solutions to major Consumer Packaged Goods (CPG) companies. Hi-Cone has set ambitious goals to become 100% recyclable, biodegradable or compostable by 2025. We realize we cannot do this alone and need to work collaboratively with consumers, governments, and industry to meet consumer’s desire to reduce their plastic use and meet the UN’s 2030 Sustainable Development Goals (SDGs). Our aim is to educate consumers on how to reduce plastic consumption and how to recycle all aspects of the circular economy; an economic system aimed at eliminating waste and the continual use of resources. We partner with consumers, retailers, and industry experts to make tangible and impactful changes to advance the circular economy through our ongoing innovations in packaging design and material development. For more information on Hi-Cone, please visit hi-cone.com or follow news on LinkedIn. To learn more about Hi-Cone’s new ring carrier recycling program, please visit RingRecycleMe.com.

About Avangard Innovative

Avangard Innovative is the worldwide leader in technology-driven circular economy solutions headquartered in Houston, Texas. With 30 years of experience operating in 11 countries, Avangard Innovative is the largest recycler in the Americas, offering full-service waste management and recycling optimization solutions at all levels of the process. Our proprietary technology (Sustayn Analytics™), program management & optimization (NaturaZero2.0™), and post-consumer resin manufacturing facilities (NaturaPCR™) are designed to help our clients measure, manage and monetize their sustainability programs. Avangard Innovative’s mission is to preserve and protect the environment by achieving zero waste to landfill. For more information, please visit avaicg.com or follow news on Facebook @AvangardInnovative or LinkedIn @Avangard-Innovative.

Jennifer Perr is the Global Sustainability Director at Hi-Cone. In this role, she collaborates with the entire value chain to both build and educate key stakeholders about the circular economy. She also leads Hi-Cone’s Vision 2025 team, focused on developing new multi-packaging solutions that continue Hi-Cone’s long history of packaging with positive end-of-life outcomes and that uphold Hi-Cone’s commitment to minimal environmental impact.

Jennifer Perr is the Global Sustainability Director at Hi-Cone. In this role, she collaborates with the entire value chain to both build and educate key stakeholders about the circular economy. She also leads Hi-Cone’s Vision 2025 team, focused on developing new multi-packaging solutions that continue Hi-Cone’s long history of packaging with positive end-of-life outcomes and that uphold Hi-Cone’s commitment to minimal environmental impact.